Tubos capilares: Tipos y aplicaciones

Los tubos capilares son tubos pequeños y delgados con un diámetro interior estrecho que desempeñan un papel esencial en diversas aplicaciones científicas, industriales y médicas. Se utilizan ampliamente en campos como la mecánica de fluidos, la medición de temperatura, la cromatografía y la refrigeración. Exploremos sus tipos, ventajas y diversas aplicaciones.

¿Qué son los tubos capilares?

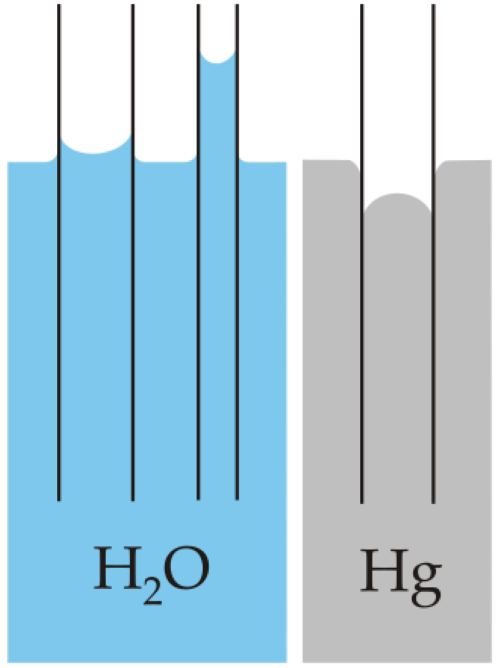

Lostubos capilares son tubos de paredes delgadas con un diámetro interno que oscila entre unos pocos micrómetros y unos pocos milímetros. Estos tubos suelen estar hechos de materiales como vidrio, acero inoxidable o plástico, dependiendo de la aplicación. La característica que los define es su capacidad para mostrar acción capilar, un fenómeno por el que los líquidos ascienden en un tubo estrecho debido a la tensión superficial. Esto hace que los tubos capilares sean útiles en aplicaciones que requieren el movimiento de fluidos o la medición de pequeños volúmenes de líquido.

Lacapilaridad se produce por la interacción entre el líquido y la superficie del tubo. Cuando el líquido se introduce en el estrecho espacio, se adhiere a las paredes del tubo, mientras que la tensión superficial del líquido hace que se eleve en contra de la gravedad. Este efecto es crucial en muchos dispositivos y sistemas que dependen del flujo preciso de líquidos. A continuación se muestra una ilustración de la acción capilar, que muestra cómo el líquido interactúa con una superficie polar como el vidrio (≡Si-OH).

[1]

[1]

Ventajas y beneficios

- Precisión en el movimiento de fluidos: Los tubos capilares son ideales para aplicaciones que requieren un control preciso del movimiento de los líquidos. Sus pequeños diámetros internos les permiten mover fluidos en cantidades pequeñas y precisas.

- No necesitan alimentación externa: Una de las principales ventajas de los tubos capilares es que funcionan basándose en fuerzas físicas naturales, como la tensión superficial y la acción capilar. Esto significa que no necesitan fuentes de energía externas, como bombas o motores, para mover los líquidos.

- Bajo coste: Estos tubos son relativamente baratos de fabricar, especialmente los de vidrio. Su bajo coste los convierte en una solución atractiva para muchas industrias en las que se necesita precisión sin necesidad de maquinaria compleja.

- Diseño compacto: Debido a su pequeño tamaño, estos tubos son ideales para aplicaciones en las que el espacio es reducido o en las que se requieren cantidades mínimas de líquido. Su compacidad facilita su integración en sistemas o dispositivos pequeños.

- Versatilidad: Los tubos capilares están disponibles en diversos materiales, como vidrio, acero inoxidable y plástico, lo que los hace adecuados para su uso en una amplia gama de entornos, incluidos los de alta temperatura o corrosivos.

Tipos de materiales de los tubos capilares

Lostubos capilares están disponibles en varios materiales, tamaños y diseños, cada uno de ellos adecuado para aplicaciones específicas. Los tipos más comunes son:

1. Tubos capilares de vidrio

Los tubos capilares de vidrio son los más utilizados y suelen emplearse en laboratorios. Son transparentes, lo que permite observar fácilmente el líquido que contienen. Los tubos de vidrio son ideales para aplicaciones en las que la visibilidad es importante, como cuando se controla el movimiento de fluidos en experimentos. También son químicamente inertes, por lo que son adecuados para una amplia gama de aplicaciones químicas.

Aplicaciones: Se utilizan en la medición de la temperatura, como en los termómetros, y en experimentos de laboratorio en los que es necesario estudiar el comportamiento de los fluidos.

2. Tubos capilares de acero inoxidable

Lostubos capilares de acero inoxidable se utilizan en aplicaciones industriales más exigentes en las que la durabilidad y la resistencia a la corrosión son cruciales. Estos tubos son ideales para aplicaciones en las que intervienen sistemas de alta presión o productos químicos agresivos. Su resistencia mecánica los hace adecuados para la manipulación de líquidos a presión, especialmente en sistemas que requieren precisión.

Aplicaciones: Comúnmente utilizados en sistemas de refrigeración, sistemas hidráulicos y dispositivos médicos.

3. Tubos capilares de plástico

Los tubos capilares de plástico, fabricados con materiales como policarbonato o teflón, son ligeros y resistentes a los productos químicos. Son flexibles y pueden moldearse en diversas formas, lo que los hace adaptables a distintas aplicaciones. Los tubos de plástico suelen utilizarse en aplicaciones menos exigentes, en las que el coste y el peso son factores importantes.

Aplicaciones: Utilizados en productos de consumo, dispositivos médicos y diversos sistemas de gestión de fluidos.

4. Tubos capilares bimetálicos

Los tubos capilares bimetálicos se componen de dos metales diferentes, que suelen estar unidos entre sí. Estos tubos se utilizan principalmente en aplicaciones de detección de temperatura porque los dos metales se expanden a velocidades diferentes, lo que les permite actuar como un interruptor sensible a la temperatura.

Aplicaciones: Muy utilizados en termostatos y sistemas de refrigeración para regular la temperatura.

Aplicaciones de los tubos capilares

Los tubos capilares se emplean en una amplia gama de sectores, desde la investigación científica hasta los procesos industriales. He aquí algunas de sus aplicaciones más notables:

1. Sistemas de refrigeración

En refrigeración, son un componente esencial del sistema de válvulas de expansión. El capilar controla el flujo de refrigerante del lado de alta presión al lado de baja presión del sistema. La presión del refrigerante se reduce al pasar por el estrecho tubo, lo que provoca su expansión y enfriamiento, dando lugar al efecto de refrigeración. Esta aplicación es común en unidades de aire acondicionado y refrigeración.

2. Termómetros

Se utilizan en termómetros de líquido en vidrio, en los que el tubo capilar contiene un líquido (normalmente mercurio o alcohol) que se expande o contrae en función de los cambios de temperatura. A medida que aumenta la temperatura, el líquido del tubo se desplaza hacia arriba, lo que permite obtener lecturas precisas de la temperatura. Los tubos capilares permiten realizar mediciones precisas incluso con cambios muy pequeños de temperatura.

3. Cromatografía

En las técnicas cromatográficas, los tubos capilares se utilizan en la cromatografía en capa fina (TLC) o la cromatografía de gases (GC). Estos tubos permiten la separación precisa de sustancias utilizando la acción capilar para mover los disolventes a través de una fase estacionaria. Esta técnica se utiliza ampliamente en el análisis químico para identificar y cuantificar los distintos componentes de una muestra.

4. Estudios de flujo de fluidos

Los tubos capilares se utilizan a menudo en los laboratorios para estudiar el comportamiento de los fluidos en condiciones controladas. Midiendo cuánto sube un líquido en un tubo capilar, los investigadores pueden determinar propiedades importantes como la tensión superficial y la viscosidad. Estos estudios son fundamentales en campos como la física, la química y la biología.

5. Dispositivos médicos

En aplicaciones médicas, se utilizan en dispositivos como tubos de extracción de sangre y equipos de muestreo de sangre capilar. Su pequeño tamaño permite recoger volúmenes muy pequeños de sangre u otros fluidos corporales, lo que resulta crucial para las pruebas de diagnóstico. Los tubos capilares también se utilizan en ciertos tipos de termómetros médicos.

6. Sistemas hidráulicos

Los tubos capilares de acero inoxidable se utilizan en sistemas hidráulicos, donde ayudan a controlar el flujo de fluido en entornos de alta presión. Estos tubos son cruciales para regular el flujo de aceite u otros fluidos en la maquinaria, garantizando un funcionamiento suave y eficaz.

7. Mecha y movimiento de fluidos

Los tubos capilares también se utilizan en aplicaciones de mecha, donde ayudan al movimiento de líquidos a través de superficies. Esto resulta especialmente útil en la absorción de líquidos en determinados procesos industriales o en la construcción de dispositivos como bolígrafos de tinta, donde la acción capilar ayuda a llevar la tinta a la punta de escritura.

Conclusión

Los tubos capilares pueden controlar con precisión el movimiento de fluidos sin necesidad de energía externa, lo que los hace muy valiosos en sistemas de refrigeración, medición de temperatura, cromatografía y dispositivos médicos.

Stanford Advanced Materials (SAM) es experta en el suministro de tubos capilares de gran pureza y precios competitivos, incluyendo acero inoxidable, aleaciones a base de níquel y metales preciosos. Ya sea para usos industriales, científicos o médicos, los tubos capilares de SAM están diseñados para satisfacer las necesidades específicas de cada cliente.

Referencias:

[1] Acción capilar. (2024, 30 de diciembre). En Wikipedia. https://en.wikipedia.org/wiki/Capillary_action#

Bares

Bares

Cuentas y esferas

Cuentas y esferas

Tornillos y tuercas

Tornillos y tuercas

Crisoles

Crisoles

Discos

Discos

Fibras y tejidos

Fibras y tejidos

Películas

Películas

Escama

Escama

Espumas

Espumas

Folio

Folio

Gránulos

Gránulos

Panales

Panales

Tinta

Tinta

Laminado

Laminado

Bultos

Bultos

Mallas

Mallas

Película metalizada

Película metalizada

Placa

Placa

Polvos

Polvos

Varilla

Varilla

Hojas

Hojas

Cristales individuales

Cristales individuales

Blanco para sputtering

Blanco para sputtering

Tubos

Tubos

Lavadora

Lavadora

Cables

Cables

Conversores y calculadoras

Conversores y calculadoras

Escriba para nosotros

Escriba para nosotros

Chin Trento

Chin Trento